What is Optical Bonding

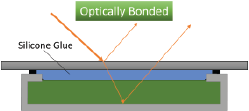

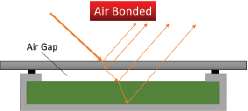

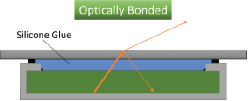

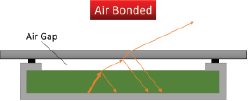

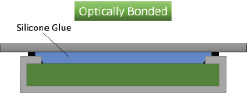

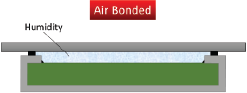

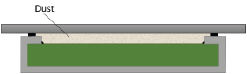

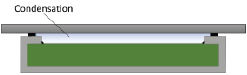

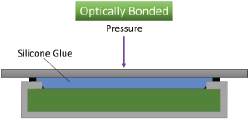

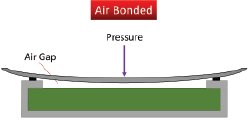

Optical bonding is the process of filling up the airgap between the cover glass / touch panel and LCD cell / module to improve the visual and material features and with that the quality and value of the bonded device.

CLEAR-BOND uses silicone based liquid adhesive with the best properties available to date for this process.

What is CLEAR-BOND

The silicone-glue formula used is the faytech-X2-1688, also known as 'CLEAR-BOND'. This formula has been specifically created to provide the best optical bonding performance in the market.

This silicone-glue formula consists of two components, referred to in the documentations as component A and B.

The silicone liquid AB-glue is especially suitable for: Large size optical bonding

Optical bonding to be used in extreme environments:

>100 ton/year

With more than 100 ton of yearly glue production, CLEAR-BOND is the leading supplier of glue for large format optical bonding.

Services & projects

CLEAR-BOND focuses on all bonding related services & projects and is a separate business unit and registered trademark of faytech, the first company bringing a large format optical bonding process into mass production.

Mechanical Test

| Test Item | Measuring Method | Test Condition | Result |

| Vibration Test | MIL-STD-810F | 1 hour | No bubble or delamination |

| Shock Test | MIL-STD-810F | 40g, 11ms pulse ±X, ±Y, ±Z axes | |

| Altitude | - | 15,000 feet above sea level, climb / descent change rate 10m/s decompression withing 15 seconds | |

| Pull Test | GB/T 1040.2-2006 | Force until separation | 0.278 N/mm2 |

| Lap Shear Test | GB/T 1040.2-2006 | 0.205 N/mm2 |

| Test Item | Measuring Method |

| High Temperature | MIL-STD-810-2003 |

| Low Temperature | MIL-STD-810-2003 |

| Constant Temperature & Humidity | IEC 60068-2-78-2012 |

| Thermal Cycle | IEC 60068-2-78-2012 |

| UV Resistance | G154-06 |

| Mechanical Shock | MIL-STD-810F |

| Vibration | MIL-STD-810F |

Besides the 'CLEAR-BOND' formula faytech-X2-1688. There are 2 other standardized formulas in the market, allowing the client to pick the best bonding glue to suit their needs:

faytech-XA-1688

faytech-T50-1688

Additionally, faytech would be able to adapt the materials properties, such as hardness, viscosity, curing speed, etc., upon request.

This is done due to possessing their own silicone formulations and own in-house production.

Comparison

Advantages of Optical Bonding

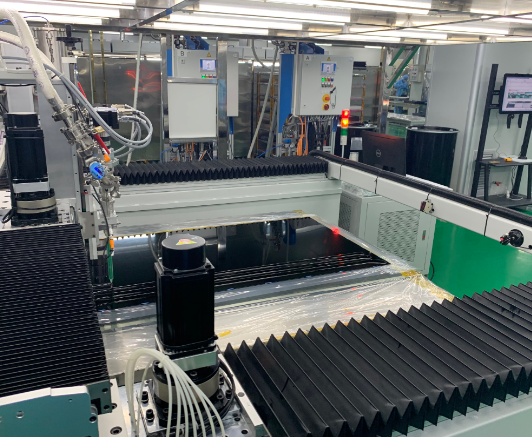

CLEAR-BOND bonding facilities and service

There are two class 100 cleanrooms available in Shenzhen and Suining in order to perform the optical bonding services.

The production area consist of 5000+ sqm altogether and has a daily optical bonding output of >500 large formats.

CLEAR-BOND provides in-house optical bonding services of cover glass / touch panel to open cell / LCD-Modules of sizes all the way up to 105 inch!

CLEAR-BOND machinery

CLEAR-BOND completely developed own bonding machinery and unique processes for large format bonding. These processes offer an outstanding production yield of 97%.

A total of three different bonding processes are available, those for small, middle and large formats. Besides this, other bonding processes include those for display modules and cells.

Services for manufacturers

CLEAR-BOND provides training, machinery and glue to world leading (touch) device and whiteboard manufacturers in order to support their in-house optical bonding production.

Tailored solution

CLEAR-BOND provides a tailored solution of German dispensers & equipment, self-developed machineries and processes (patented) together with experienced project managers.

CLEAR-BOND glue production

CLEAR-BOND is produced within the clean room using high quality containers and equipment.

Samples of all production lots are stored and secured over long periods of time while being tested on a regular basis for stability and conformity (temperature, consistency, pull & shear test, haze, etc.).

CLEAR-BOND Technical Data

Cured Mixture of components - faytech-X2-1688 - 'CLEAR-BOND'

| Typical Characteristics | Measuring Method | Value |

| Color | - | Clear |

| Yellowing Index | ASTM E313-15e1 | <1 |

| Density at 23 °C | ISO 2781 | 0.97 g/cm³ |

| Penetration (150 g hollow cone) | DIN ISO 2137 | 220 ±20 mm/10 |

| Relative Permittivity | IEC 60250 | 2.7 |

| Dielectric Strength | GB/T 1693-2006 | 400 µm/m°C |

| Volume resistivity | GB/T 1692-92 | 1015 Ω cm |

| Surface resistivity | IEC 93 | 1014 Ω |

| Refractive index | nD25 | 1.404 |

| Flame retardancy | - | 94 HB |

| Transmission (path length 1.5 mm) | - | > 98.9 % |

| Thermal conductivity | GB/T 10297-1998 | 0.20 W/m K |

| Coefficient of linear thermal expansion | ISO 11359 - 1- 2014 | 300 x 10-6 m/m K |

| Temperature Range | - | -40 to 85 °C |

| Shrinkage | - | < 0.1 % |

Uncured components A and B - faytech-X2-1688 - 'CLEAR-BOND'

| Typical Characteristics | Measuring Method | Value |

| Color | - | Clear |

| Viscosity at 23 °C | ISO 3219 | Typ. 1000 mPas Min. 800 mPas; Max. 1200 mPas |

| Density at 23 °C | ISO 2781 | 0.97 g/cm³ |

| Haze | ASTM D 1003 | < 0.3 % |

Catalyzed Mixture of components A + B - faytech-X2-1688 - 'CLEAR-BOND'

| Typical Characteristics | Measuring Method | Value |

| Platinum-catalyst in component | - | B |

| Mixing ratio | A : B | 1 : 1 |

| Viscosity of mixture | ISO 3219 | 1000 mPas Min. 800 mPas; Max. 1200 mPas |

| Pot life at 23 °C | - | 150 min |

| Curing method | - | Hydrosilylation |

Uncured components A and B - faytech-T50-1688

| Typical Characteristics | Measuring Method | Value |

| Color | - | Clear |

| Viscosity at 23 °C | GB/T 10247-2008 | typ. 500 mPas |

| Density at 23 °C | ISO 2781 | 0.99 g/cm³ |

| Haze | ISO7027-1999 | < 0.2 % |

Catalyzed Mixture of components A + B - faytech-T50-1688

| Typical Characteristics | Measuring Method | Value |

| Mixing ratio | A : B | 1 : 1 |

| Pot life at 23 °C | - | > 2h |

Cured Mixture of components - faytech-T50-1688

| Typical Characteristics | Measuring Method | Value |

| Color | - | Color |

| Density at 23 °C | ISO 2781 | 0.99 g/cm³ |

| Penetration (Needle) | GB/T269 | 240 ±15 mm/10 |

| Relative Permittivity | IEC 60250 | 2.7 |

| CTE | GB/T 20673-2006 | 400 µm/m°C |

| Dielectric Strength (25°C) | GB/T 1693-2007 | 20 kV/mm |

| Dielectric Constant (25”C) | GB/T 1693-2007 | <3.0 (1MHz) |

| Refractive index | nD25 | 1.404 |

| Transmission (path length 1.5 mm) | UV-VIS | > 99 % |

| Thermal conductivity | GB/T 10297-1998 | 0.20 W/m K |

| Temperature Range | - | -60 to 140 °C |

| Shrinkage | - | < 0.1 % |

News

Contact

E-Mail:

sales@clear-bond.com

Address:

CLEAR-BOND

2nd Floor, plant No.2, Xingye Science Park, Huiyang District,

Huizhou City, Guangdong Province, China

Tel:

+86-755-89580612